Tips for Maintaining Scuba Cylinder Health

Out of all your scuba diving equipment, your scuba cylinder is the unsung hero of it all. We have a tendency to focus on the quality and maintenance of the wetsuits, BCDs and regulators of wherever we go diving, but not on the most important feature of your scuba equipment, and your lifeline.

Scuba cylinders are filled with filtered, compressed air. The air is taken through the air intake of the compressor and passes through a filtration system, where particles and moisture are filtered out of it. However, even with the proper filtration systems, scuba cylinders still need to be inspected once in a while to ensure that they are in proper working order. The two inspection requirements are the visual inspection and hydrostatic test.

1. Visual inspection

Scuba cylinders should be visually inspected once a year by a qualified visual cylinder inspector. In a visual inspection, we empty the tank, take the valve off the top of the cylinder and take a look inside for corrosion, aluminum alloy build-up and moisture. Whenever you dive somewhere, make sure to check for the visual inspection sticker. If it's not there, ask the dive center when their last visual inspection was.

Always check visual inspections before you dive

2. Hydrostatic testing

Scuba cylinders should normally be tested every two to five years, based on local laws and regulations. In a hydrostatic test, the cylinder is normally filled to 5/3 of its normal fill capacity, and then cylinder walls' flex is tested. Hydrostatic testing is imperative to maintaining the integrity of tanks, and therefore imperative to maintaining your safety. Scuba cylinders will have the last date of hydrostatic testing embedded into them. Most local laws and regulations will not exceed five years for hydrostatic testing requirements, so if the last date of testing was over five years ago, make sure to ask about it.

This tank was hydrostatically tested in May 2013

Here are some tips to help maintain your scuba cylinders:

1. Don't ever empty a tank completely.

Pressure inside the tank prevents water from entering it. Make sure never to empty your tank too quickly either, as that can cause condensation to build up on the inside and outside.

2. Have your tanks filled only by reputable scuba air stations

If a guy is filling scuba tanks out of the back of his van, the air probably isn't going to be super clean. Remember, even minute percentages of contamination, such as carbon monoxide, will be greater under pressure, so you want to make sure your air is clean to prevent such issues.

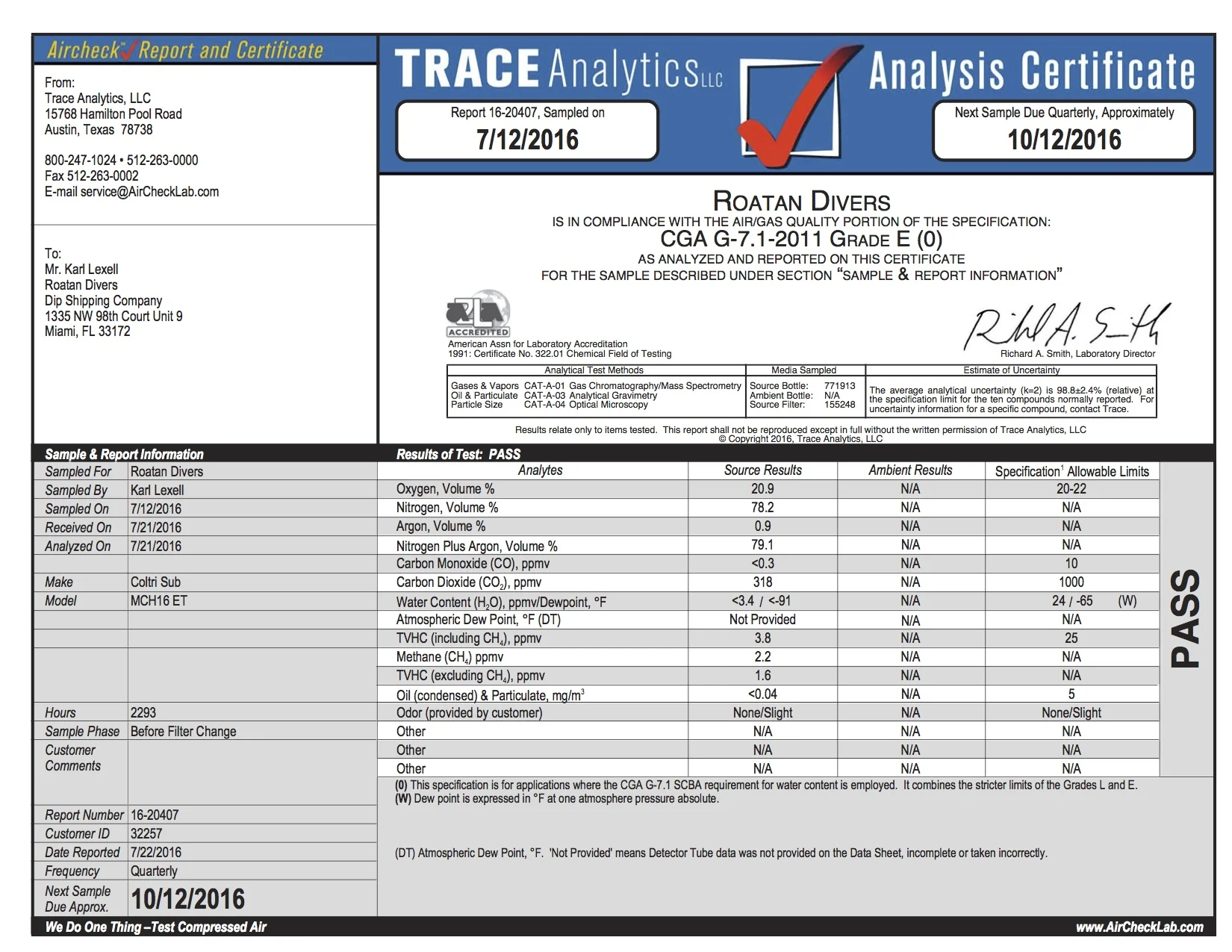

An analysis certificate from Trace Analytics, based on a quarterly air sample

Air stations should get their air tested, preferably quarterly. We use Trace Analytics, an independent testing lab in Texas. We send them air samples every three months, and they send back the results to let us know if the air passes. Air testing is a great way of also checking on the compressor's health, because if the air doesn't pass, it's a sign that there may be something wrong with the compressor as well.

3. Store your cylinders in a cool, dry place

Extreme heat is the death of scuba cylinders, so avoid putting them under extra pressure and keep them out of the sun. Also make sure to keep them standing in a cool, dry place where they can't get knocked over.

Our scuba cylinders are such an important part of our scuba equipment, so make sure not to neglect them! Remember, maintenance is key when it comes to anything, so keep all of your scuba gear well-maintained and serviced and you will get many years of diving with them.

Happy diving!